The choice of materials is a fundamental aspect when 3D printing. There are several options available, such as common plastics, plastics for engineering and industry, resins It is metallic materials. Each one has specific characteristics and it is important to consider factors such as the type of project, the desired properties and the printing technology used. In this guide, we will explore the different types of materials for 3D printing, its qualities and offer practical tips to help in proper choice.

Main points

- Choosing the right material for 3D printing is essential to achieving high-quality results.

- Different types of materials, such as plastics, resins It is metals, offer specific features to meet project needs.

- To the desired properties, the printing technology used and the applications of the part must be considered when choosing materials.

- In addition to choosing the material, it is important to follow best preparation practices and print under ideal conditions.

- Proper storage of filaments and post-processing of parts also influence the print quality 3D.

Types of Materials for 3D Printing

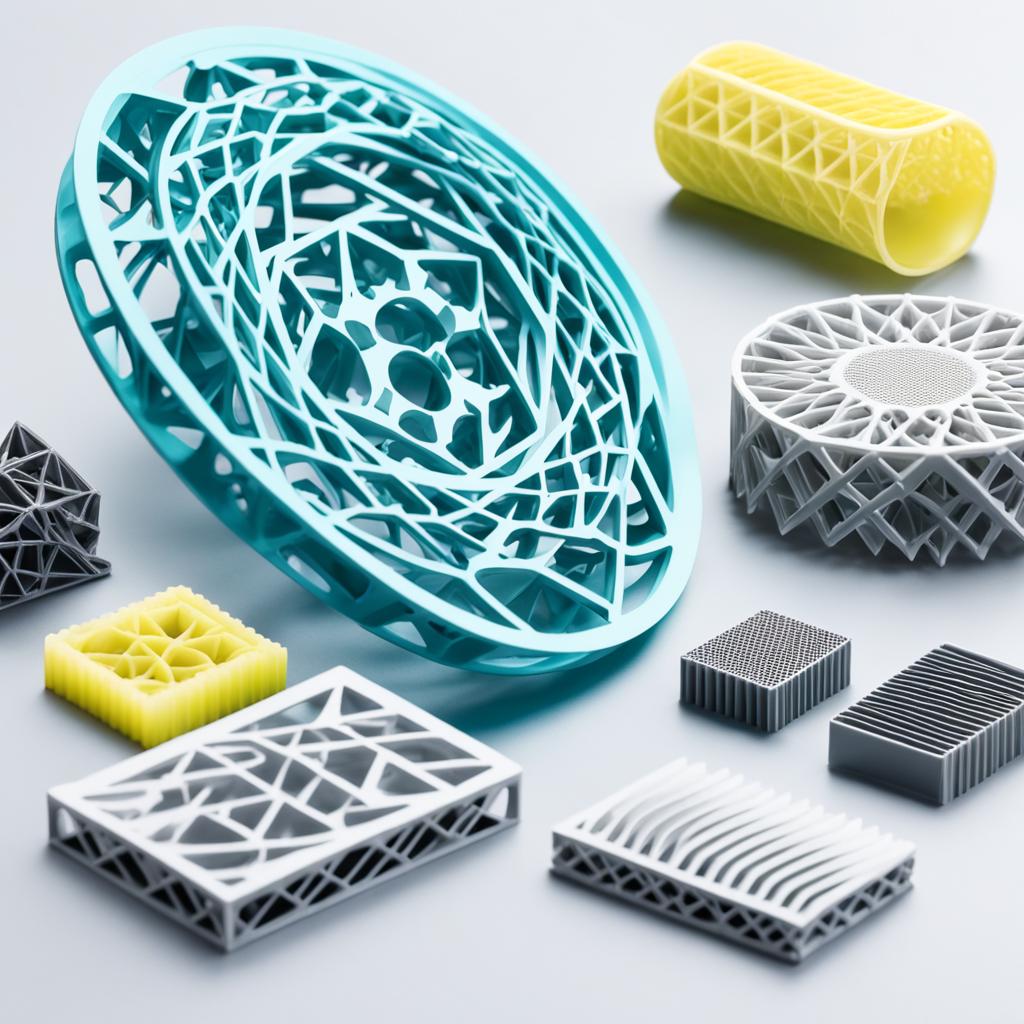

You 3D printing materials can be divided into four main categories: common materials, plastics for engineering and industry, resins It is metals.

You common materials, as ABS, PLA It is PETG, offer distinct features and wide application in 3D printing. The ABS is known for its strength and durability, the PLA is biodegradable and easy to print, and the PETG has similar thermal and mechanical resistance to ABS, but without odor.

You plastics for engineering and industry, as PRAÇA It is nylon, are used in applications that require high strength and durability. The PRAÇA is a plastic resistant to impact and high temperatures, while the nylon is known for its excellent mechanical and chemical resistance.

Resins are used in precision 3D printing, offering precise details and quality finishes. They can be thermolytic, which hardens when heated, or photosensitive, which hardens when exposed to light.

You metals are another category of 3D printing materials. It is possible to print metal parts directly using metallic materials, such as titanium alloy, stainless steel and even precious metals such as gold and silver.

Advantages of 3D Printing Materials

You common materials offer a wide range of options, from biodegradable plastics to strong and durable materials. Engineering and industrial plastics have specific characteristics that make them suitable for demanding applications. Resins allow for high-precision and detailed printing. Metals allow for the creation of parts directly from metallic materials, opening up new possibilities for design and functionality.

In the table below, we highlight some examples of 3D printing materials in each category:

| Common Materials | Plastics for Engineering and Industry | Resins | Metals |

|---|---|---|---|

| ABS | PRAÇA | Thermolytic Resin | Titanium Alloy |

| PLA | Nylon | Photosensitive Resin | Stainless steel |

| PETG | Precious Metals |

When choosing material for 3D printing, it is important to consider factors such as desired properties of the final part, compatibility with the 3D printer used and the specific application of the part. Each material has unique characteristics that meet different requirements, and the proper choice will result in high quality and performance prints.

See too:

Characteristics of 3D Printing Materials

Each type of 3D printing material has specific characteristics, and it is important to know its properties before choosing the most suitable one for your project. Below, we highlight some characteristics of the main materials used in 3D printing:

ABS (Acrylonitrile Butadiene Styrene)

- Resistance and durability;

- Good adhesion between layers;

- High impact resistance;

- Resistant to high temperatures;

- May emit odor during printing.

PLA (Polylactic Acid)

- Biodegradable;

- Easy to print;

- Wide range of colors available;

- Does not emit odor during printing;

- Lower mechanical resistance compared to ABS.

PETG (Glycol Modified Polyethylene Terephthalate)

- Thermal and mechanical resistance similar to ABS;

- Transparency and brightness;

- Does not emit odor during printing;

- Resistance to humidity and UV rays.

PC (Polycarbonate)

- High impact resistance;

- High transparency;

- Resistant to high temperatures;

- Chemical resistance;

- Used in industrial and engineering applications.

Nylon

- High strength and durability;

- High impact resistance;

- Flexibility;

- Chemical resistant;

- Applied to mechanical and functional parts.

Resins

- Various options of thermolytic and photosensitive resins;

- Precise details and smooth surfaces;

- Wide variety of colors and finishes;

- Used in precision 3D printing and prototyped models.

Metallic Materials

- Stainless steel, titanium alloy and precious metals available;

- Possibility of printing metal parts directly;

- Wide application in sectors such as jewelry, aerospace and dentistry.

These are just a few of the characteristics of materials for 3D printing most commonly used. It is important to consider the desired properties for the final part, analyze the design requirements and choose the material that best suits your needs.

| Material Type | Main Features |

|---|---|

| ABS | Strength and durability; good adhesion between layers; high impact resistance; resistant to high temperatures; may emit odor during printing. |

| PLA | Biodegradable; easy to print; wide range of colors available; does not emit odor during printing; lower mechanical resistance compared to ABS. |

| PETG | Thermal and mechanical resistance similar to ABS; transparency and brightness; does not emit odor during printing; resistance to humidity and UV rays. |

| PRAÇA | High impact resistance, high transparency, high temperature resistant, chemical resistance, used in industrial and engineering applications. |

| Nylon | High strength and durability; high impact resistance; flexibility; resistant to chemicals; applied in mechanical and functional parts. |

| Resins | Various options of thermolytic and photosensitive resins, precise details and smooth surfaces, wide variety of colors and finishes, used in precision 3D printing and prototyped models. |

| Metallic Materials | Stainless steel, titanium alloy and precious metals available, possibility of printing metal parts directly, wide application in sectors such as jewelry, aerospace and dentistry. |

Considerations When Choosing 3D Printing Materials

When choosing materials for 3D printing, it is important to consider several issues to ensure that the choice is suitable for your needs. Considerations when choosing materials for 3D printing include:

- Material Properties: Evaluate the desired properties for the final part, such as strength, flexibility, transparency, or electrical conductivity. Each material has unique characteristics that can vary significantly.

- 3D Printing Technology: Make sure the material you choose is compatible with your 3D printer technology. Not all materials will work on all machines, so it’s important to consider compatibility before making your choice.

- Specific Applications: Consider the end use of the printed part. Depending on the project, you may need specific materials for prototyping, mass production, decorative objects, or functional parts. Be sure to select the material that best suits your intended application.

By taking these considerations into account, you’ll be better equipped to choose the right materials for your 3D printing needs. Careful material selection is essential to ensuring the quality and functionality of your printed parts.

Choosing the Right Material for Your Project

Choosing the right material is a crucial step when undertaking a 3D printing project. To ensure that the final part meets your needs, it is important to consider the desired properties, 3D printing technology used and carry out tests with different materials to find the most suitable one.

Desired Properties

Before choosing a material, you need to define the desired properties for the final part. Depending on the project, you may need materials with high strength, durability, flexibility, transparency or electrical conductivity. Consider which characteristics are most important in the context of your specific project before making a final decision.

3D Printing Technology

Another important factor to consider is the 3D printing technology that will be used. Not all materials are compatible with all printers, so check your printer's specifications to ensure that the material you choose is suitable. Additionally, each printing technology may have specific requirements regarding the materials used, so be aware of these demands when making your selection.

There are several 3D printing technologies on the market, including FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering), each with their own characteristics and material requirements.

Tips for Choosing 3D Printing Materials

- Conduct research and consult reliable sources for information about available materials and their properties.

- Consider the final application of the printed part and which properties are most relevant to your design.

- Check your 3D printer's specifications to ensure the material you choose is compatible.

- Experiment with different materials and test to assess the quality of your prints and their suitability for your project requirements.

Choosing the right material is essential to ensure quality 3D printing and meeting the needs of your project. When considering the desired properties and the 3D printing technology used, you will be on the right track to choosing the most suitable material and achieving excellent results in your 3D prints.

Tips for Quality 3D Printing

To achieve a quality 3D print, it is important to follow some essential tips. One of the first steps is to properly prepare the 3D printer. This includes leveling the printing bed to ensure a flat and stable surface. In addition, check the adhesion between the material used and the printing bed to avoid displacement issues during the process.

Another crucial aspect is to adjust the printing temperature according to the specifications of the selected material. Each material has an ideal temperature range to ensure proper melting and part stability. Be sure to consult the manufacturer's recommendations and make any necessary adjustments in the 3D printer software.

Additionally, consider performing temperature adjustment tests to get the best results. Incorrect temperature can lead to issues such as shrinkage or warping of the part during the printing process. Therefore, monitor the temperature closely and make necessary adjustments as needed.

Remember that the print quality 3D printing can also be affected by other factors, such as print speed, print layers, and proper cooling of the parts. By following these 3D printing tips and best practices, you’ll be well on your way to achieving high-quality parts and satisfying results.

“The quality of a 3D print depends on proper preparation of the printer, correct temperature adjustment and adherence to good practices throughout the process.”

Additional Care and Considerations

When using 3D printing, it is important to keep in mind a few additional care and considerations to ensure quality and safety results. In addition to choosing the right material and following best practices, other aspects also deserve attention.

Filament Storage

Proper storage of filaments is essential to prevent damage and prolong the life of the materials. Make sure to store the filaments in a dry place, protected from moisture. Use sealed containers or ziplock bags to avoid exposure to air. Also, keep the filaments away from sources of excessive heat and direct sunlight, as this can compromise their physical and chemical properties.

Post-processing of Printed Parts

O post-processing of printed parts is also an important aspect to consider. After printing, it is common to need to perform some finishing to improve the aesthetics or functionality of the piece. This may include processes such as sanding to smooth the surfaces, applying paint or varnish, and even gluing the printed parts separately. Check the specific recommendations for each material used and follow the appropriate techniques to obtain the best results.

Safety in the Use of Materials

A safety in the use of materials is essential. Always follow the manufacturer's guidelines and recommendations regarding the handling, storage and disposal of materials. Some filaments may emit harmful vapors or particles during the printing process, so it is important to use a well-ventilated environment or adopt protective measures, such as the use of respiratory protection masks. In addition, avoid direct contact with the skin and eyes, especially when handling chemicals used in the post-processing of the parts.

Following these additional care and considerations, you will be on the right path to obtaining satisfactory results in your 3D prints, preserving the quality of the materials and prioritizing safety in their use.

Conclusion

Carefully choosing materials for 3D printing is essential to ensure quality results and meet the needs of your specific project. With a wide variety of options available, each material has unique characteristics and specific applications. To make the proper choice, it is important to consider the desired properties for the final part, the 3D printing technology used and the specific applications of the piece.

By analyzing the desired properties, such as strength, flexibility, transparency, or electrical conductivity, you will be able to select the material that best suits your project. Additionally, it is important to evaluate the material’s compatibility with your 3D printer to ensure a successful print. By following additional tips and precautions, such as storing filaments correctly and performing proper post-processing of parts, you will be on the right track to achieving high-quality 3D prints.

Therefore, by considering all this information and choosing the right materials for 3D printing, you will be ensuring the quality and effectiveness of your project. Remember to explore the characteristics of each material, seek guidance from manufacturers and perform tests before starting the final print. With patience and dedication, you will be able to achieve great results and take advantage of all the advantages of the world of 3D printing.